A Complete System Ready for You to Brand and Customise

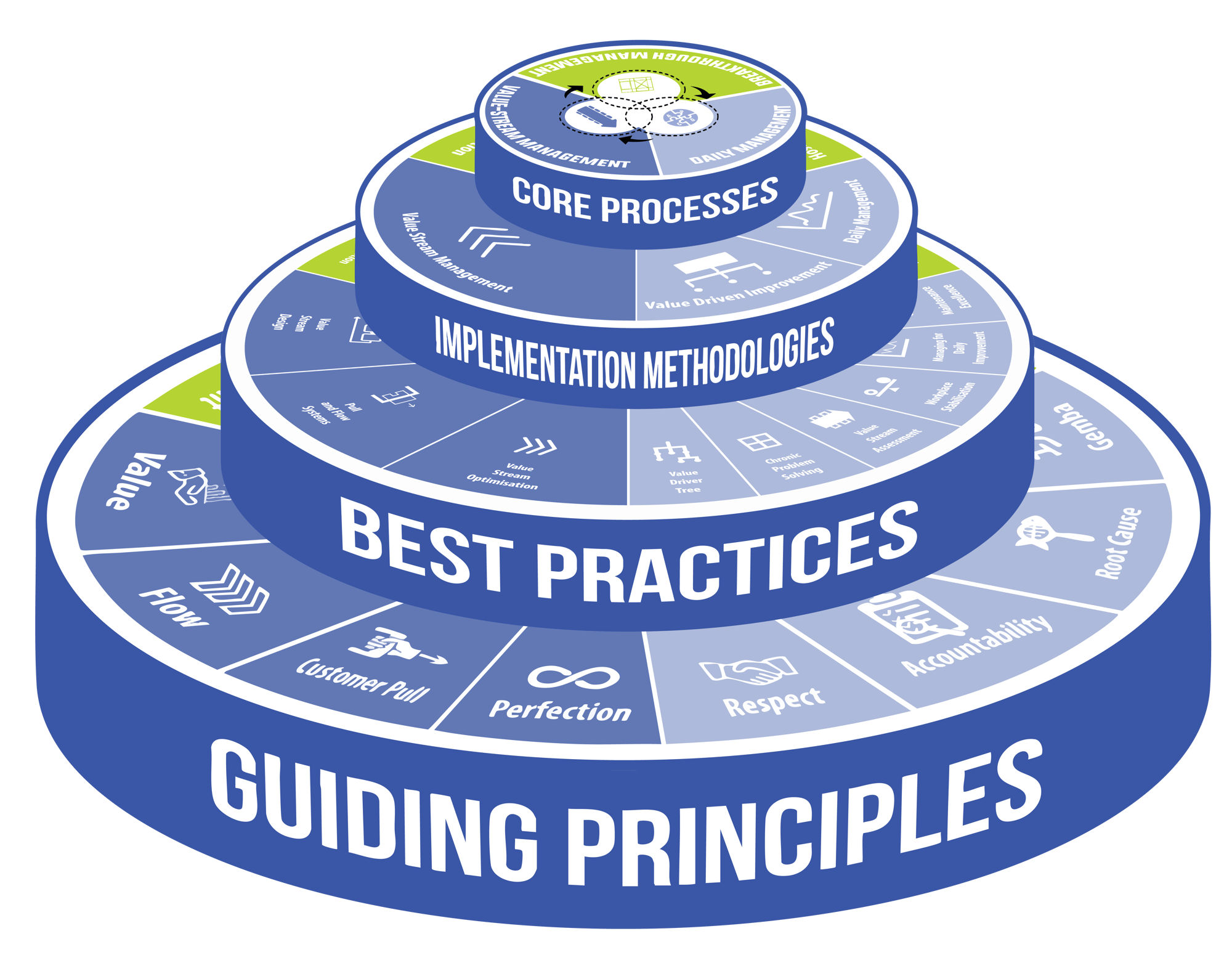

The Breakthrough Business System is the product of over two decades studying, and working closely with, some of the world’s most successful organisations. It’s more than a comprehensive set of training materials with some tools and templates thrown in for good measure – it’s a cohesive “system” of integrated resources designed from the ground-up to simplify the job of establishing a world-class operating system from your organisation.

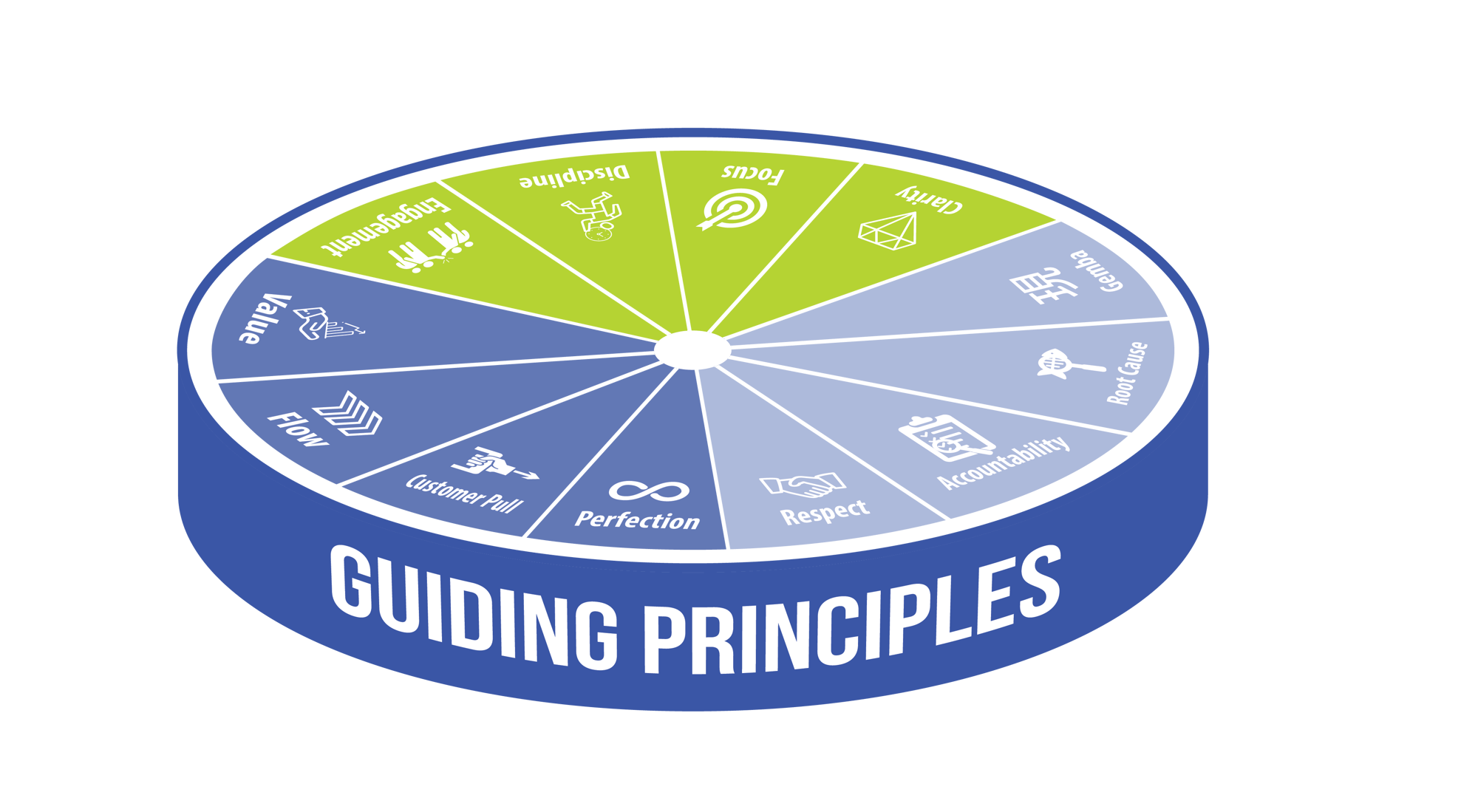

Whilst our experience is that there is no one best way to implement lean or drive execution of strategy, we have come to learn that there are a common set of guiding principles that underpin the success of any high-performance organisation. These guiding principles are the foundation of the Breakthrough Business System and all other resources in the system have been carefully designed to ensure that as they are used the outcome is the continual reinforcement of these core principles.

⬤ The Breakthrough Business System is Built on 12 Guiding Principles

01 Focus

Do Less to Achieve More

By improving focus, we ensure we work only on the critical few, rather than the trivial many, to achieve more.

02 Clarity

Take Aim Before You Shoot

By increasing clarity, we remove ambiguity/ensure better causal thinking, ensuring we choose more of the right things to do, and through this focus, better results.

03 Alignment

Engage Those Who Will Execute the Plan

By improving alignment, we ensure greater commitment to a more realistic plan by engaging the people who will execute the plan in developing it.

04 Discipline

Establish Habits that Sustain Execution

By improving discipline we create a high-performance culture by establishing habits that reinforce the right behaviours and build and reinforce problem solving muscle.

05 Respect

Value Those That Do the Work

By increasing the level of respect those closest to the work we increase engagement fostering a culture of collaboration and improvement, leading to better outcomes.

06 Accountability

Create Ownership for Improvement

By increasing accountability we ensure individuals understand exactly what they are responsible for and through this feel greater ownership for improvement leading to higher levels of performance and job satisfaction.

07 Root Cause

Solve the Problem for Good

By constantly seeking the root cause we remain focused on finding and addressing the underlying cause of any problem not just containing or alleviating its symptoms - ultimately avoiding recurrence the same problem in the future.

08 Gemba

Go to the Place the Work is Done

By always going to the Gemba we observe the reality, understand problems more accurately and inherently implement more practical solutions.

09 Value

Eliminate Non-value-added Activity

By focusing relentlessly on value we ensure our efforts are directed towards activities that genuinely benefit the customer, leading to improved efficiency, reduced waste, and ultimately, higher customer satisfaction and profitability.

10 Flow

Strive to Reduce Bottlenecks

By always aiming for flow we strive to reduce interruptions in the movement of work, leading to faster delivery, reduced waste, and higher quality - ultimately enhancing customer satisfaction and profitability.

11 Pull

Only Produce on a Demand Signal

By only triggering production when the customer “pulls” for a produce or service we are aligning production with actual customer demand, reducing waste, optimizing resource utilization, and enhancing efficiency and flexibility.

12 Perfection

Seek Better Every Day

By relentlessly seeking perfection (whilst never letting perfect be the enemy of better) we never lose sight of the fact that improvement is a never-ending journey, and every process can always be improved.

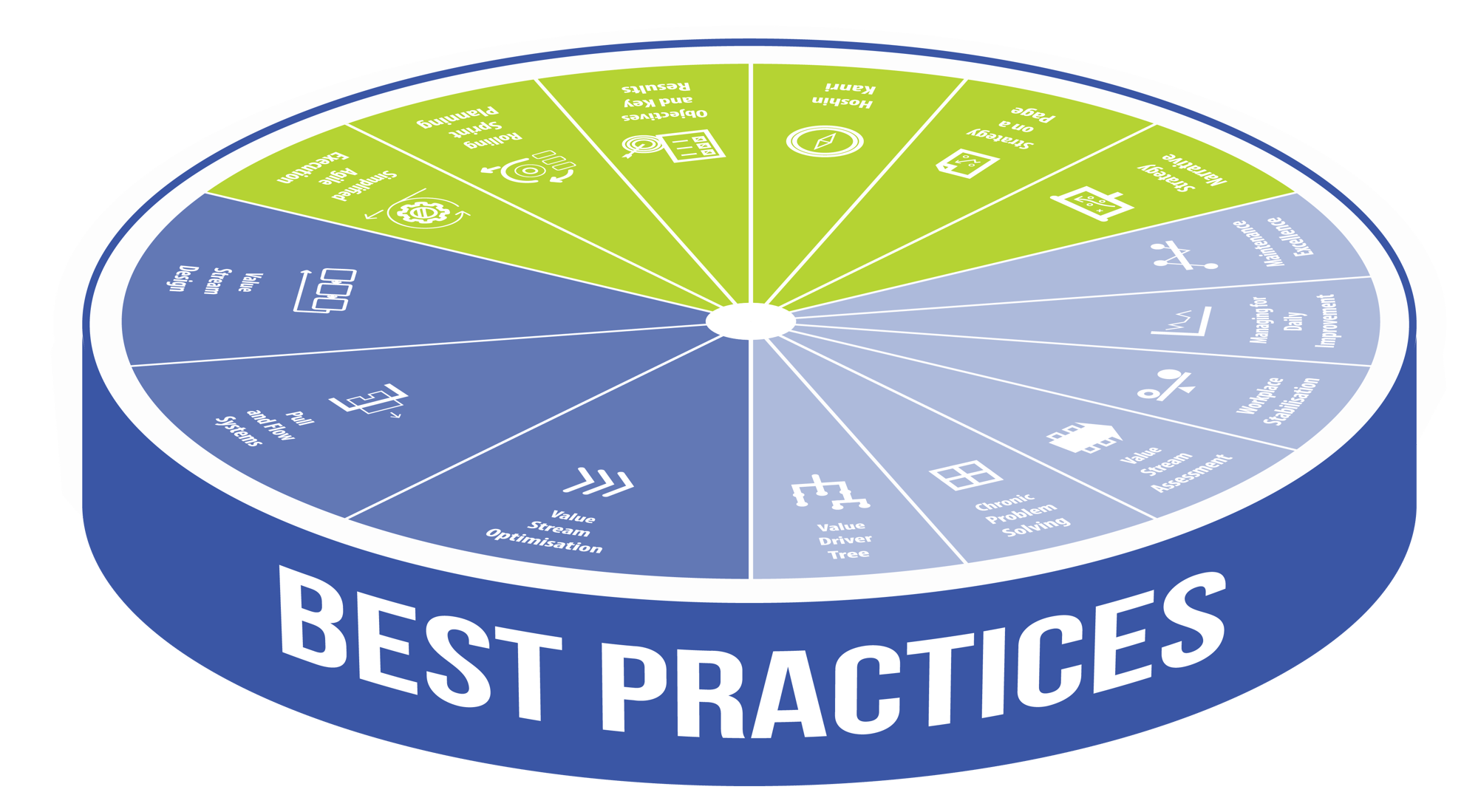

We designed the Breakthrough Business System to give organisations the flexibility to decide which core best practices they wish to incorporate in their Lean Business System. Some best practices are essentially interchangeable – you can base your Strategy Deployment process, for example, on either Hoshin Kanri or OKRs, Each practice has its pros and cons. Or you can choose to incorporate different best practices into your system to support operating units at different level of maturity. If you would like to know more or have one of our experts walk you through the pros and cons of different options, please request a call back.

⬤ Explore the Best Practices Included in the Breakthrough Business System

Strategy Implementation (Breakthrough) System:

► Strategy Refinement

Strategy Narrative/Canvas

A Strategy Narrative is a succinct description of an organisation’s strategy – in narrative form typically on a single A3 page. This narrative typically captures the longer-term (vision) state that the organisation is seeking to achieve, the current state that it is starting from, the strategic options that it faces, the options it has chosen, and why, and finally how those options translate into a critical few medium-term breakthroughs.

The Strategy Narrative can be complemented with a Strategy Canvas which then further elaborates the intermediate medium-term state that the organisation is expecting to reach in the next 3-5 years (in terms particularly of the key indicators that describe the progress of the expected transformation) enabling the “glide path” between the current and future state to be better articulated and conceptually “tested” before we start to implement. It also provides a means to track at a macro level the execution of the overall strategy.

Strategy On a Page

Strategy on a Page (SoaP) is an approach to developing and documenting strategy on a page that focuses on distilling the strategy in a format that favours conciseness/ease of presentation of the strategy. Typically, this format covers the organisation’s purpose/mission, vision, values, focus areas, objectives, initiatives/activities and metrics.

Strategy on a Page can be used at different levels in an organisation and can be used to “deploy” strategy as is the case with strategy deployment frameworks that use this approach such as OGSM (Objectives, Goals, Strategies and Metrics) which uses a form of “Strategy on a Page” format. Whilst the Strategy on a Page approach produces a strategic plan that is less descriptive of the logic of the strategy than, for example, the Strategy Narrative approach, the resulting plan is typically easy to understand and as such can be used to communicate the strategy within the organisation.

► Strategy Deployment

Hoshin Kanri

Otherwise known as Hoshin Planning, Strategy Deployment, Policy Deployment, Priority Deployment, Goal Deployment or Strategic Goal Deployment, Hoshin Kanri originated in Japan in the 1960s.

The term Hoshin Kanri meaning “compass management” was first coined by Bridgestone Tyres in a 1965 report analysing the planning techniques used by Deming Prize winners including Kobe Shipyards.

At the heart of Hoshin Kanri is the idea of applying the Deming closed loop Plan, Do, Check, Act (PDCA) problem solving process to ‘created’ problems not just ‘existing’ problems – like “how will we achieve this breakthrough objective?”

Objectives and Key Results

Objectives and Key Results is a goal-setting framework used by individuals, teams, and organizations to define measurable goals and then track their outcomes.

The development of OKRs is generally attributed to Andrew Grove who introduced the approach to Intel in the 1970s. The investor, John Doerr, introduced the concept to Google, where it has been used to good effect and later published a popular book on the approach “Measure What Matters” published in 2017.

According to Doerr, an Objective is what you want to accomplish. A good Objective is significant, concrete, action-oriented and inspirational. Objectives can be set annually or over an even longer term. A Key Result is how you will accomplish it. Good Key Results are specific, timebound, aggressive yet realistic, measurable and verifiable. Key Results are usually set quarterly and evolve as work progresses.

► Strategy Execution

Rolling Sprint and Action Planning

This discipline requires strategic actions to be “chunked” down into quarterly sprints and the implementation of a rolling (typically quarterly) cycle that simultaneously identifies new work (improvement actions) to be prioritised into the rolling plan, develops the scope of that work until is ready to implement whilst in parallel executing the priority actions.

This approach enables significant agility, ensures that the organisation is not taking on too much in parallel and typically results in a step change in the proportion of targeted outcomes that are successfully realised and an increase the confidence that is built within the organisation as to the ability to execute the plan.

Simplified Agile Project Management

Simplified agile project management is a form of agile project management in which the core concepts of agile (without implementing all aspects, for example, of agile methodologies like SCRUM) are applied to manage a set of improvement actions. In the case of simplified agile project management, the proxy for customer “value” are the key results, or outcomes – typically articulated for objectives that have been cascaded from higher level operational, or strategic, goals.

The key of simplified agile is to break the improvement projects down into smaller “stories” (discrete chunks of work that will lead to process/product changes) that can be that can be delivered in a series of shorter iterative cycles e.g. shorter, cycles. Prioritisation within each iteration is then based on contribution of each story to the key results.

This approach differs from rolling sprint and action planning (which also employs an agile approach) is that the “sprint” duration is much shorter, and the planning/prioritisation of work is performed at a more detailed “story” level.

Operational Excellence (Production) System:

► Build the Foundation

Value Driver Tree

The Value Driver Tree approach involves the systematic decomposition of value outcomes e.g. Return on Capital Employed to the underlying process/operational drivers of that value. The concept is based on the belief that if we understand the relationship between these value drivers and the outcomes, we can improve the outcomes by focusing on improvement in performance of indicators we use to quantify the drivers.

The logic behind the Value Driver Tree approach is that are some level the financial/stakeholder outcomes translate to operational/process variables that individual managers within an operating unit can be accountable for. By linking the Core Value Driver Tree concept to the PDCA improvement cycle (Chronic Problem Solving) we can then systematically focus our improvement effort on closing the gap to our targeted performance on the driver variable that have the largest impact on the desired outcome, safe in the knowledge that this effort will lead ultimately to improvement in the overall outcome.

Chronic Problem Solving

Chronic Problem Solving is the practice of applying systematic problem-solving methodologies to solve recurring/significant problems that cannot easily be solved at the front-line by those completing the work. There are multiple methodologies that can be employed to solve chronic problems that are all fundamentally based on the Deming PDCA cycle.

These range from A3 thinking (which involves using a structured A3 sized format that walks through the logic and stages of the PDCA cycle and helps organise the thinking of the individual/team undertaking the improvement), through rapid kaizen events (which compress the application of the improvement cycle into a short highly structured timescale) to more complex methodologies like DMAIC (Define, Measure, Analyse, Improve and Control) which also follows the PDCA cycle but attempts to address variation in the inputs and outputs of a process by converting the business problem to a statistical problem, finding a statistical solution and translating that statistical solution back into a business solution.

► Standardise and Stabilise

Value Stream Assessment

Value Stream Assessment is an approach that seeks to identify the value streams within an operation by first identifying the “routings” through the operation that “families” of products (or services) that share similar steps in their product and similar work content to produce.

The goal of Value Stream Assessment is to ultimately re-organise/re-orient the way we view the operation from the perspective of these “value streams” so we can move from a functional (resource centric) view of production to a cellular (product centric) view of production, which in turn ultimately enables us to synchronise production of a product and realise the ultimate objective of creating consistent smooth flow of value in line with customer demand.

Value Stream Assessment (sometimes called PQ-PR or Product Quantity-Product Routing analysis) is an essential step in understanding the key steps in any value stream and ultimately helping to define the boundaries of “cells” within any overall value stream.

Workplace Stabilisation

Workplace Stabilisation is the practice of standardising and stabilising parts of a value stream (e.g. a production cell) or parts of a production operation (e.g. a functional production area) if that operation is not already organised on a value stream basis.

The practice combines the concept of workplace organisation (through the systematic application of 5S (Sort, Simplify, Sweep, Standardise, Sustain) with standardisation (definition of standard work to cover the activity scope of the cell/area) plus basic levelling of the process steps such that the cell/area is capable of producing outputs at the customer demand rate.

This levelling of the time taken to complete individual process steps is typically achieved through a combination of line balancing i.e. re-distribution of work/resources between process steps and reduction in work required in bottleneck operations through the elimination of non-value-added work and/or optimisation of the time taken to do that work by resequencing of activities.

Managing for Daily Improvement

Managing for Daily Improvement (MDI) is an approach to managing operations that focuses on making continuous improvement a daily habit by empowering employees at all levels to identify and solve problems. The foundation of MDI is standard work and the continual observation of the process to determine if the standard work is being followed and if that standard work is leading to good (or defective) outputs).

Typically, visual controls are used by cell/area teams to highlight the exception condition i.e. when the process is producing defective outputs and so-called SDQC (Safety, Delivery, Quality and Cost) visual management boards are utilised with tiered huddles to capture the analysis of problems and identify/capture the actions identified to address the root cause of the problem. Typically Managing for Daily Improvement is supported by leadership standard work which clarifies accountability for improvement and implements a schedule of Gemba walks in which leaders “walk” the flow of the operation providing support to the front-line teams as they drive improvement of the process.

Maintenance Excellence

Maintenance Excellence is an holistic approach to proactive maintenance of production equipment that focuses on reduction of downtime. It integrates best practices from Total Productive Maintenance including planned maintenance, autonomous maintenance and early equipment management. Maintenance Excellence builds on the daily management foundation established through the deployment of Workplace Stabilisation, Chronic Problem Solving and Managing for Daily Improvement.

Building on the visual controls introduced through Managing for Daily Improvement, Maintenance Excellence also focuses on establishing a robust OEE (Overall Equipment Effectiveness) based measure of production losses at constraint equipment as a means to track the progress towards perfect production. This measurement is used both to assess the impact of the other practices of Maintenance Excellence are having in terms of reduced downtime, reduced performance losses and reduced quality losses as well as to identify opportunities to further improve our preventative maintenance activities. Finally Maintenance Excellence also integrates where meaningful, the practice of Predictive Maintenance to optimise equipment availability and reduce unnecessary maintenance activity.

► Create and Optimise Flow

Value Stream Design

Value Stream Design is a method for optimising a production process by mapping and analysing the flow of materials and information to identify areas for improvement. It involves examining the current state of a value stream, then designing a future state that optimizes it for speed, efficiency, and reduced waste.

Once the current state value stream for a specific product/process family has been mapped, the Value Stream Design approach applies design principles to create a future state design in which every cell within the value stream can operate at the takt rate, the demand trigger is as close to the customer as possible and in which flow is created by connecting the cells via one of the three primary pull-based systems i.e. a sequential pull system (sometimes known as one-piece flow), a first-in-first-out (FIFO) lane system or a replenishment pull system (sometimes known as the “supermarket” system).

Pull and Flow Systems

Flow is created when the upstream activities only produce when there is a demand trigger from the downstream activities. This “chain of pull signals” creates flow.

The goal in implementing flow is to achieve, where possible, continuous flow i.e. when consumption of an item by a downstream activity triggers the next in chain upstream activity to produce a replacement (often called one-piece flow).

Where continuous flow is not possible i.e. where there is imbalance in the cycle times of the process steps, or where the process must produce different items which have different work content/need different resources, other strategies may be required to achieve flow. These include the introduction of connectors that introduce the necessary buffer inventory needed to manage the imbalance (but still pass replenishment/pull signals from downstream activities to the upstream activities) such as FIFO Lanes and Supermarkets and/or the implementation of process improvements which attack the process constraints and enable the process to move closer to continuous flow by, for example, reducing change-over time and removing non-value-added activity.

Value Stream Optimisation

Once flow has been established, further strategies can be employed to improve productivity, improve quality and reduce lead time and ultimately improve customer satisfaction/profitability. These strategies include demand levelling (Heijunka Scheduling) in which knowledge of customer demand patterns is utilised to optimise flow by levelling production i.e. by distributing the production more evenly, both in terms of volume and product mix, over time.

Other strategies that support Value Stream Optimisation include poke-yoke (mistake proofing) to prevent/eliminate defects in production and Jidoka ("automation with a human touch“) which is based on the twin concepts of stopping production immediately when abnormalities are detected (to prevent defective products from being produced) and improving productivity through separation of human and machine work (to increase the proportion of work that is automated and eliminate the need for people to be simply watching over machines).

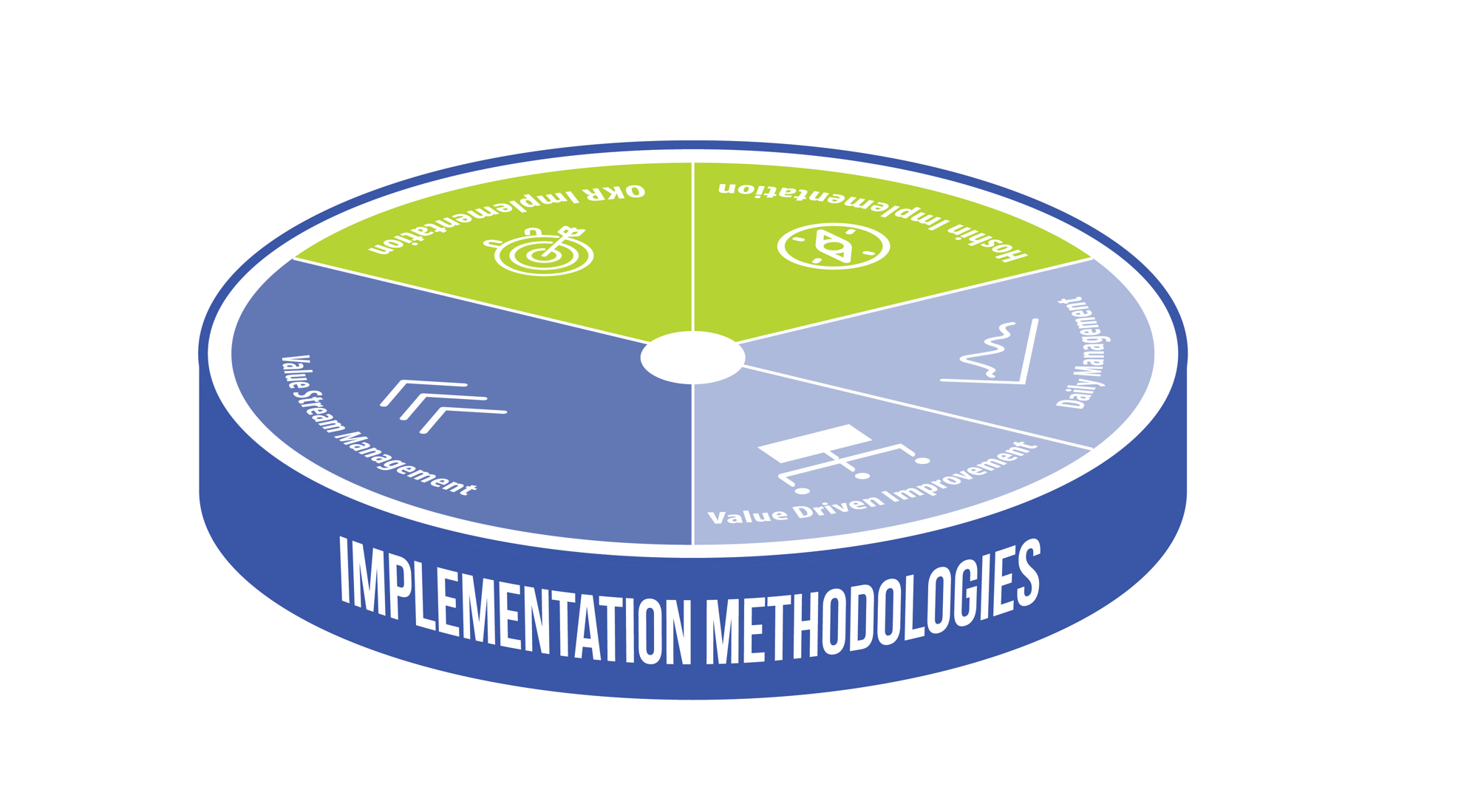

Incorporated in the Breakthrough Business System are five robust implementation methodologies. Collectively these methodologies provide proven roadmaps for implementing a complete Breakthrough (Strategy Implementation) System (based on either a foundation of Hoshin Kanri or OKRs) as well as a comprehensive Production (Operational Excellence) System based on Lean best practices.

We have deliberately divided our overall Lean (Production System) implementation process into three distinct phases (each with its own methodology roadmap) to enable organisations to choose a starting point that best mirrors the current state of lean adoption.

⬤ Explore Our Implementation Methodologies

▶ Hoshin Driven Strategy Implementation

Our Hoshin Driven Strategy Implementation methodology implements a complete Hoshin Kanri based Breakthrough (Strategy Implementation) System that simultaneously reinforces key strengths of the Hoshin Kanri concept, whilst addressing key weaknesses that we have learnt often lead to less successful Hoshin implementations.

This methodology implements the Strategy Narrative/Canvas process as the basis of strategy refinement, leverages the best of Hoshin Kanri and A3 thinking to ensure effective deployment of strategy and the Agile based best practice of Rolling Sprint and Action Planning to chunk execution into quarterly sprints and enable rapid adjustment of the plan when things don’t play out as we assumed or hoped they would.

▶ OKR Driven Strategy Implementation

Our OKR Driven Strategy Implementation methodology implements a complete Objectives and Key Results (OKR) based Breakthrough (Strategy Implementation) System that simultaneously reinforces the key strengths of the OKR concept, whilst addressing the key weaknesses in the process that we have learnt are the root cause of many of the less successful implementations.

This methodology implements the Strategy on a Page (SoaP) approach as the basis for as structured strategy refinement process, introduces the concepts of cascaded OKRs to support strategy deployment and links the quarterly OKR planning cycle with Simplified Agile Project Management to create a robust execution process for the resulting action plans (one that breaks scope down into smaller iterations and enables relentless focus on achievement of the key results..

▶ Value Driven Improvement Implementation

Our Value Driven Improvement implementation methodology is designed to help organisations with low lean maturity build a solid foundation for successful lean deployment. It focuses on engaging the management of any operating unit in applying a Plan-D-Check-Act (PDCA) improvement cycle to the most important drivers of value in each operating unit.

Leveraging the Value Driver Tree concept, the methodology establishes a simple management system in which the accountability within the operating unit for improvement of the indicators used to track leading and lagging value drivers is clarified and a periodic management review cycle established. This management review cycle leverages the concept of a MAAR (Measure-Analyse-Action-Review) chart which encourages each accountable manager to apply PDCA thinking to continuously identify and address the next most important reason why the indicator is not meeting the desired target.

Once implemented, Value Driven Improvement helps create the conditions for successful lean deployment by ensuring leaders at all levels are directly engaged in continuous improvement, understand intimately the value of the work and have accountability for driving improvement on a daily basis.

▶ Daily Management Implementation

Our Daily Management implementation methodology builds on a foundation of leadership ownership for continuous improvement by extending problem solving to front-line operational teams. The methodology is designed to be implemented in any production environment, regardless if it is organised on a value stream (organisation by the process needed to produce a specific product family) or functional (organisation by shared resources that many products may pass as they are produced) basis.

The methodology includes an optional element of Value Stream Assessment which enables organisations to first identify the value streams before implementing daily management in the production “cells” that the selected value stream decomposes into.

Once the individual production cells (or production areas in the case of a functionally organised production operation) have been identified, this methodology provides a repeatable and highly scalable model to first organise, standardise and stabilise each cell/area before then implementing the other critical components of daily management (visual management, tiered huddles, Leader Standard Work, problem solving, kata coaching, Gemba walks etc) as well as, were appropriate, best practices for maintaining production equipment.

▶ Value Stream Management Implementation

Our Value Stream Management methodology is designed to build on the foundation of Daily Management by designing and implementing a new future state value stream design in which flow of value to the customer is optimised.

The first stage of the methodology applies value stream design principles to identify what pull system “connectors” and/or process improvements/rebalancing will be required to create flow across the value stream. The second stage of the methodology then implements a series of flow “kaizens” that implement this new value stream design to achieve as close to one-piece flow as possible (within the constraints of the operation/product mix). The final stage of the methodology then seeks to further improve lead-time, productivity and quality by applying strategies to optimise the flow such as Mistake Proofing (Poke Yoke), Demand Levelling (Heijunka Scheduling) and Autonomation (Jidoka).

In addition to establishing and optimisig flow, the Value Stream management implementation methodology also establishes a value stream level review process that creates a focus for on-going improvement of the value stream and creates the mechanism to ensure the design meets the evolving customer/stakeholder expectations in terms of lead-time, quality performance and value creation.

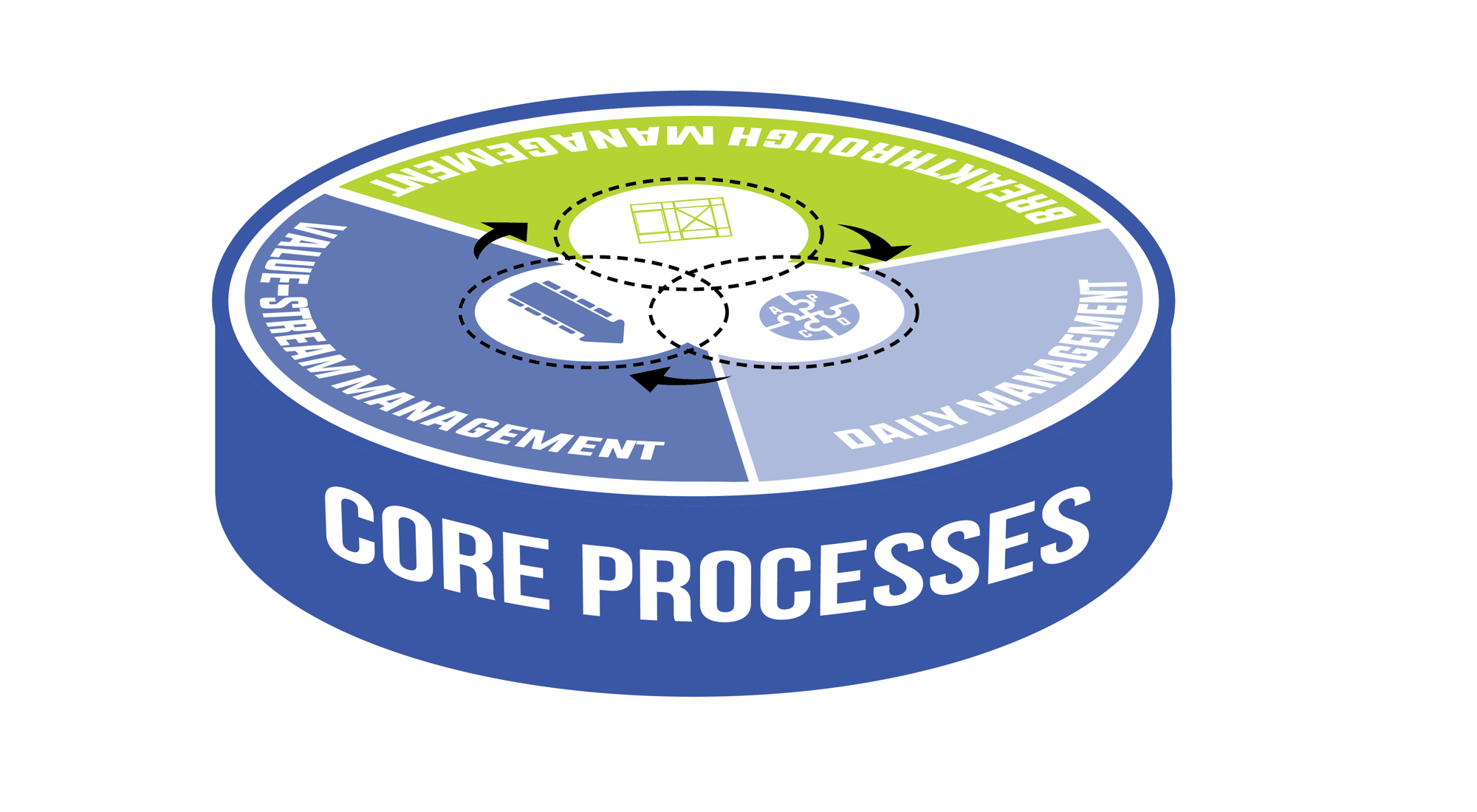

At the highest level, we can think of the Breakthrough Business System as consisting of three core processes (organised into two main systems) which codify how the organisation implements transformational breakthroughs (Breakthrough Management), drives daily execution of the operating plan (Daily Management) and optimises the delivery of products and services to customers (Value Stream Management). Collectively these process provide a blueprint for how the organisation can mange the competing challenge to stay both competitive and relevant at the same time.

⬤ Explore the Core Processes

▶ Breakthrough Management

Breakthrough Management is the management process by which we systematically implement transformational breakthroughs (step changes) that position us to win in the future.

The Breakthrough Management process effectively codifies how the organisation refines, deploys and executes strategy. The ultimate goal of the process is ensure the organisation remains relevant and can continue to grow value either by successfully implementing its strategy or by being agile enough to pivot/adapt when its clear a new strategy is needed.

▶ Daily Management

Daily Management is the management process by which we engage all employees in standardising and continuously improving existing operations at the front-line (where the work is done).

The Daily Management process effectively codifies how front-line employees identify deviations from standards and consistently apply systematic problem solving to continuously improve operational performance (raise standards). This process also defines how chronic problems are escalated, where needed, for resolution and how leaders support and enable the front-line and chronic problem-solving processes.

▶ Value Stream Management

Value Stream Management is the management process by which we implement the cross-functional improvements that ensure existing end-to-end processes deliver the value customers expect

The Value Stream Management process effectively codifies how Value Stream Design principles are applied to create flow, and how complementary concepts such Change-over reduction (SMED), Mistake-proofing (Poke-yoke), Demand-levelling (Heijunka Scheduling) and Autonomation (Jidoka) can be applied to continue to move as close to continuous (one piece) flow as possible.

Whether You Want to Improve Your Game or Change the Game Breakthrough Partners Can Help

Navigate the Change

Learn how Breakthrough Partners can help you build, and remove barriers to, the individual, team and organisational adaptability needed to thrive in an ever more disrupted and hyper-connected world.

Explore Our Training

Explore the options we offer to help build the skills and know how you need to successfully implement and sustain your organisation's lean business system.